Bromoacetic Acid: From Lab Curiosity to Chemical Workhorse

Historical Development

Chemistry classrooms often touch on the iconic halogenation reactions, yet the practical journey of bromoacetic acid began much earlier in the spirited experimentation of nineteenth-century scientists. This simple-looking compound emerged as a pivotal player for organic synthesis, inviting curiosity when Russian and German chemists started investigating halogen-substituted acetic acids. Its history isn’t buried in faded journals. Researchers struggled and succeeded in isolating bromoacetic acid’s biting, almost vinegary aroma, learning soon after that swapping out a methyl hydrogen for a bromine atom gave rise to intense reactivity. Industrial interest picked up steam across Europe and North America, especially as new synthetic dyes, anesthetics, and pharmaceuticals required precise carbon scaffolds—where bromoacetic acid fit neatly as a building block. Decades of trial and error behind glassware sparked new manufacturing methods, widely adopted by academic and commercial labs for peptide synthesis, cancer drug research, and more.

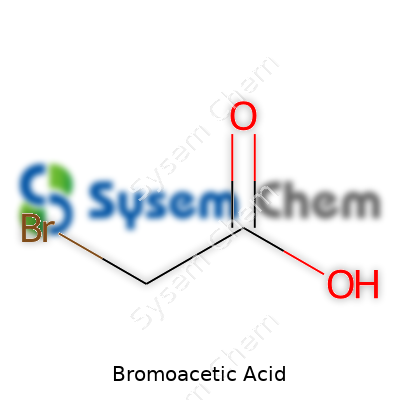

Product Overview

Bromoacetic acid earns its keep in chemical inventories thanks to a unique blend of simplicity and punch. At its core sits a two-carbon backbone, where a bromine atom replaces one hydrogen sidekick next to the carboxyl group. This single swap turns a mild-mannered acetic acid molecule into a powerful alkylating agent. Commercial supplies label it by several names: 2-bromoacetic acid, BAA, or just “bromoacetate.” You’ll spot it as a white to faintly yellow solid—sometimes crystalline, often clumping into stubborn lumps if exposed to moisture. Strong, acrid fumes lift off the surface, especially if left uncapped at room temperature. Because of this, bottles often arrive sealed tight and packed under inert gases.

Physical & Chemical Properties

Pure bromoacetic acid displays a melting point near 50 degrees Celsius, although an open bottle can soon draw in water, pushing that point lower. Its solubility spans the gap from water to most polar organics. Pour a bit into chilled water, and the solid vanishes fast, producing a slightly acidic, slightly sharp solution. By weight, the heavy bromine gives it a density just over 1.85 g/cm3. Its molecular formula, C2H3BrO2, hints at its straightforward structure, and yet the presence of bromine makes it highly reactive in nucleophilic substitution reactions. Acidity levels land in the strong range (pKa about 2.9 for the carboxyl group), creating a sour punch compared to straight acetic acid. Over time and with improper storage, the compound degrades, so chemical suppliers stress air-tight, low-temperature, and moisture-free environments.

Technical Specifications & Labeling

Regulations in the EU, US, and across Asia require clear hazard labeling on the bottle. Look for pictograms signaling corrosive risks and a red “acute toxicity” symbol. Purity grades often run from 98% up to 99.5%, with trace impurities like dibromoacetic acid or unreacted acetic acid kept below 0.5%. Suppliers specify melting point, water content, and identity using NMR and IR spectra. Manufacturers rely on barcode traceability, from drum to shipping crate, with safety data sheets included in every batch. Each container often displays the UN number 1760, denoting corrosive liquids, and lots targeted for research cite compliance with standards from the American Chemical Society or similar organizations.

Preparation Method

The go-to route for making bromoacetic acid starts with plain acetic acid. Chemists bubble bromine gas through a cold solution of glacial acetic acid, letting light, a Lewis acid, or small amounts of red phosphorus coax the reaction. The bromine swaps places with a methyl hydrogen, creating bromoacetic acid plus hydrobromic acid as a byproduct. In well-equipped labs, extra distillation or recrystallization steps pull off remaining water and unreacted acid. Environmental controls are critical at every step; leftover bromine gas causes headaches for operators and regulators. Years ago, this reaction required glass columns and tedious stopcock manipulations, but process chemistry has updated workflow to closed reactors and continuous monitoring, boosting yields and reducing exposures.

Chemical Reactions & Modifications

Bromoacetic acid’s star quality rests on the reactivity of the bromomethyl group. It acts as a textbook electrophile, attracting nucleophiles in everything from nucleic acid modification to amino acid synthesis. Chemists reach for it to add carboxymethyl groups onto peptides, preparing designer analogs for enzyme inhibition assays. Alkaline hydrolysis turns bromoacetic acid into glycolic acid, one rung closer to countless biochemicals. Reacting it with amines or thiols generates N- or S-substituted acetic acids—a trick used in building enzyme inhibitors or crosslinking proteins. In industry, it stands tall as a source material for the antiarrhythmic drug amidarone, certain herbicides, and even polyester manufacturing. It’s rare to see such a brief molecule land so many roles on the global stage.

Synonyms & Product Names

Walk through chemical catalogs and you’ll spot bromoacetic acid wearing several hats: 2-bromoethanoic acid, monobromoacetic acid, acetic acid bromide, or simply “bromoacetate.” Brand labels match the supplier’s legacy: Sigma-Aldrich, TCI, Alfa Aesar, Acros, and Fisher all stock it, typically in amber bottles or sealed ampoules. For customs and shipping, paperwork sometimes uses the United Nations shipping designation, UN 3265. The broad spread of synonyms can lead students or procurement teams astray, so careful cross-checks ensure the right bottle lands on the right shelf.

Safety & Operational Standards

No chemist takes bromoacetic acid safety lightly. Direct contact with skin or eyes produces quick, fierce burns. Inhalation of dust or vapor means immediate throat and lung irritation. The U.S. Occupational Safety and Health Administration (OSHA) and European Chemicals Agency (ECHA) require engineering controls, fume hoods, and chemical-resistant gloves as standard gear. Emergency showers and eyewash stations need to be within arm’s reach wherever work happens. Spills call for full-face protection and swift neutralization using sodium bicarbonate or spill control pads. Beyond the lab, strict shipping protocols classify it as a regulated hazardous material, with special packaging and paperwork. Regular staff training refreshes the knowledge of hazards and first-aid measures. Ignoring these guardrails is unthinkable in today’s chemistry world.

Application Area

Bromoacetic acid might seem niche, but it underpins major innovations in life science and materials. It’s indispensable in peptide and protein modification, gene tagging, fluorescent probe synthesis, and medicinal chemistry for anti-cancer and antiviral drugs. In agriculture, it serves as a starting point to craft more complex herbicides. Industrial chemists loop it into the mix for producing esters, intermediates in polymer manufacturing, and bleach precursors. Materials researchers find new uses almost yearly, leveraging its unique reactivity for developing advanced polymers or smart surfaces designed for environmental response. I’ve personally watched student theses unfold around this acid. Its versatility arises from the combination of high reactivity with manageable control—if handled correctly.

Research & Development

Academic labs and industry groups continue unlocking new potential for bromoacetic acid. Medicinal chemistry teams test variations to create more effective enzyme inhibitors and imaging agents. Polymer scientists experiment with bromoacetic acid to introduce functional groups onto biodegradable plastics or hydrogels. Synthetic biologists work out new routes for introducing bromoacetate units into bioengineered proteins, enabling targeted drug delivery or gene editing. Researchers probe mechanisms, developing safer and cleaner syntheses that cut waste and improve atom economy. Advanced analytical studies use isotopically labeled bromoacetic acid, helping dissect biochemical pathways inside living cells. The research pipeline never quite empties; as our needs shift, the acid’s chemistry responds with new upgrades.

Toxicity Research

Toxicologists focus on both acute and chronic risks from bromoacetic acid. Acute exposures in rats and mice cause convulsions, lung damage, or death above certain doses, which closely mirrors its burning effect on human tissues. Chronic exposure data show potential effects on central nervous systems, but gaps remain for long-term outcomes. Water utilities and environmental agencies track small amounts as disinfection byproducts in treated water, leading to toxicology studies for safe exposure thresholds. Since the acid readily enters cells via the same transporters as acetic acid, even small spills or exposures deserve immediate attention. Research into less hazardous alternatives or improved neutralization methods keeps safety near the top of the agenda wherever it sees use.

Future Prospects

Technological advances stand to reshape the role of bromoacetic acid in synthesis and manufacturing. Greener manufacturing processes, using less hazardous reagents or recyclable solvents, gain momentum year by year. Automated synthesis platforms pull bromoacetic acid off the shelf and pin it onto complex intermediates in closed reactors. As the demand for precision medicine grows, chemical biology and drug discovery continue seeking tailor-made building blocks; bromoacetic acid’s small size, coupled with its intense reactivity, keeps it relevant. Recent material science breakthroughs—like responsive polymers or self-healing coatings—point to new applications built on modified bromoaceate chemistries. Investment in better detection, handling, and neutralization technology will further reduce risks. Chemistry education circles should stay ahead of regulatory trends, safety innovations, and research breakthroughs. The story of bromoacetic acid is a reminder: even modest molecules can shape entire fields, one reaction at a time.

Bromoacetic Acid at a Glance

Bromoacetic acid represents one of those behind-the-scenes players in labs and factories. As a chemical with both bromine and acetic acid in its structure, it acts like a handy building block—one that doesn’t get much attention outside science circles. Even so, it helps push medical and industrial progress further along.

Versatility in Pharmaceutical Development

Pharmaceutical chemists count on bromoacetic acid for synthesizing drugs that treat everything from infections to cancer. By making subtle changes to molecules, researchers can tweak a medicine’s potency or safety. Bromoacetic acid helps here by making it easier to attach new parts, speeding up the journey from concept to actual pills. That isn’t just science jargon—tiny reactions like these shape the treatments people rely on every day.

This compound also appeared in my own time around small research labs. Scientists talk about “introducing functional groups” with almost the same excitement others reserve for playoff games. Bromoacetic acid gets chosen because it does this job, and does it with minimal fuss, offering reliability when schedules run tight in pharmaceutical timelines.

Role in Specialty Chemicals and Dyes

Not every use for bromoacetic acid ends up in a pharmacy. The chemical industry taps into it as an intermediate for manufacturing specialty chemicals and dyes. Take certain colorants and herbicides—the building blocks behind them often trace back to a bottle of bromoacetic acid. Its reactive nature lets it help create products used in textiles, agriculture, and even plastics.

Companies don’t toss random chemicals together. They weigh factors like reactivity, cost, and safety. Bromoacetic acid grabs attention because it reacts in predictable ways, letting big chem plants churn out batches consistently. Companies play it safe, knowing a bad batch of dye or an unpredictable herbicide can create bigger setbacks.

A Tool for Biochemistry

Proteins shape biology, and mapping how they work means modifying their structure. Bromoacetic acid lets biochemists change specific amino acids in a protein chain. This process, known as “alkylation,” gives scientists a way to learn what each part of a protein does—or even design proteins with new abilities.

I remember watching postgrad students in biochemistry nervously handle tiny vials of bromoacetic acid while talking about Nobel-winning research that relied on similar strategies. Simple chemicals power big discoveries.

Handling Hazards and Seeking Safer Alternatives

Bromoacetic acid doesn’t belong in everyone’s toolkit. It produces strong fumes and can harm the skin or lungs without proper protection. Workers and researchers stick to glove boxes, masks, and fume hoods as a routine, not an afterthought. One manager I knew drilled emergency routines into new staff—he’d witnessed the fallout after someone ignored safety labels.

Companies and labs now look for greener routes or less hazardous stand-ins, aiming to trim chemical waste and protect those handling the materials. Green chemistry pushes toward alternative reagents or improved ventilation. These changes take time, but experience shows old habits get replaced by better ones, especially with new regulations and social pressure.

Keeping Purpose in Focus

Bromoacetic acid reminds us that even small, tough-to-pronounce chemicals play big roles. It stands out in labs for its reliability and versatility, and while it comes with risks, the scientific community pushes for safer practices and constant improvements. The journey from raw chemical to finished product relies on this balance—progress shouldn’t overlook the safety of the people making it happen.

Understanding the Basics

Think about bromoacetic acid for a moment. In labs and chemical industries, it’s not that obscure. This compound carries a clear formula: C2H3BrO2. That chemist down the street who always has splashes on his lab coat probably knows it by heart. The formula tells us the molecule holds two carbons, three hydrogens, a bromine atom, and two oxygens—straightforward but packed with impact in scientific work.

What’s the Point of Knowing the Molecular Formula?

People might shrug and say, “So what?” Understanding a chemical’s guts, what pieces it’s put together from, affects safety, industrial handling, and medical possibilities. It’s also about the way those atoms line up. Adding a bromine to acetic acid changes everything. Now, this stuff can serve as a strong alkylating agent. School chemistry books only scratch the surface—real-world chemistry deals with a deeper level.

Recognizing C2H3BrO2 as the fingerprint for bromoacetic acid means more than labeling bottles. The bromine atom comes with weight—literally, it’s heavy, and it gives this molecule more muscle when it meets other compounds. It shows up as a building block for drugs, herbicides, dyes, and research tools. Drop the wrong formula into a reaction and the outcome can slip into danger territory: toxic fumes, wasted chemical batches, or risky side-products.

Why Bromoacetic Acid Matters

This compound isn’t gentle. The human body reacts strongly to it—corrosion, harmful exposure, all the usual warnings. Still, it grabs attention in drug design and molecular biology. Professionals use its reactive carbon-bromine group for modifying amino acids or working on DNA. So the formula is the start of a long journey. Without understanding the recipe, there is no progress toward safe synthesis, safe storage, and meaningful discoveries.

There’s a real challenge: balancing the power of a useful chemical with the right safety and disposal protocols. The Environmental Protection Agency (EPA) warns about brominated organic compounds. Unchecked, bromoacetic acid spills threaten water systems and soil health. That isn’t theory—there are reports of toxic runoff traced back to careless chemical management. Regulatory agencies don’t just slap labels on these chemicals for fun; they’re following data and harm reduction strategies.

Better Practices, Safer Outcomes

It pays to take formulas like C2H3BrO2 seriously. Anyone using bromoacetic acid in research or manufacturing should keep up with best practices for personal protective equipment (PPE), fume hood use, and waste disposal. The American Chemical Society (ACS) provides guidelines updated constantly with new research. Real safety means more than ticking boxes; it requires an understanding of what makes a chemical dangerous or useful at the atomic level.

Included with the safe use is transparency. Companies succeeding today show their work—detailing how much, where, and why a chemical like bromoacetic acid is handled. That’s not just regulation; it builds trust across the supply chain and the community.

Looking Ahead

Chemistry keeps charging forward—faster, greener, safer. Bromoacetic acid’s molecular formula isn’t just academic—it's a gateway to better drugs, better crops, and a better grasp of molecular biology. Getting the formula right starts everything on the right foot. The future asks for responsible stewardship for every reactive molecule in the toolkit, not just bromoacetic acid. C2H3BrO2, written on a drum or a lab notebook, means a lot when it’s connected to environmental safety and innovative health research.

Understanding the Risks

Bromoacetic acid stands out as a strong irritant, both to skin and the respiratory system, and it carries corrosive qualities. A splash can cause burns or blisters, while inhalation leads to irritation or worse. I once worked in a lab where mishandling this substance sent a colleague to the emergency room with respiratory troubles. It’s not dramatic to say that careful storage matters a lot.

Temperature and Container Choices

Bromoacetic acid breaks down under heat, giving off toxic fumes. Keep it below 30°C for safety. Direct sunlight in a storage room easily pushes temperatures above this during summer, so storing it in a dark, cool cabinet makes sense. Glass bottles work best since this acid can react with certain plastics and metals. I've seen poorly stored chemicals ruin shelving and leak onto lower levels, causing a mess and risk.

Use bottles with tight-sealing lids—as bromoacetic acid tends to evaporate by itself in a warm room, vapor quickly builds up. Replace damaged or loose lids. For extra confidence, secondary containers like sealed plastic bins add a useful layer of spill protection.

Keep It Isolated

Certain chemicals react violently with bromoacetic acid. For example, strong bases, oxidizers, and another acid called sodium hypochlorite all spell trouble. Combine these by accident and you can expect a hazardous reaction, sometimes even a fire. Separate storage cabinets help, and careful labeling—on containers and shelves—goes a long way. Regular audits of your storeroom cut down on forgotten bottles ending up where they shouldn’t.

Ventilation and Air Quality

Good airflow in the chemical store cuts the risk of vapor build-up, especially when bottles get opened or if a slow leak flies under the radar. Ducted ventilation serves as a must-have in labs and companies; at home, keeping everything in a fume hood or a room with windows you can open wide is much safer than relying on a regular cabinet.

Personal Protection: No Shortcuts

Never try to handle this acid without gloves or safety goggles. Even small spills bother skin or eyes within moments. Wear a lab coat, use tongs for moving bottles, and make sure an eyewash station and emergency shower stand nearby. The one time our team skipped gloves for a “quick job” turned into an afternoon in urgent care. Nobody wants a repeat of that.

Local Rules and Fire Codes

Some cities demand chemical stores to maintain logbooks, keep fire extinguishers nearby, and pass regular safety inspections. OSHA and EPA list bromoacetic acid in their hazard tables—meaning proper signage and safety plans aren’t just smart, they’re law. Even in a school or a startup’s tiny lab, getting a chemical safety sheet and following it closely keeps everyone in the clear.

Best Practices: Maintenance and Disposal

Check containers often—look for crystals forming on threads, which signal slow leaks. If a bottle turns sticky or stinks more than usual, remove it right away, following your hazardous waste protocols. Don’t just pour leftovers down the sink; those fumes wind up in water systems and hurt wildlife. Call your waste contractor or use a drop-off site. Better yet, never buy more than you plan to use in the next few months.

Building a Culture of Safety

Training everyone who steps into the storage area makes the real difference. Encourage questions and regular refreshers. Share those close-call stories with new staff or students—few people repeat someone else’s mistake if they hear how bad it went. With clear rules, teamwork, and honest reminders, serious accidents never become routine.

Why People Care About Bromoacetic Acid Safety

Few folks have a bottle of bromoacetic acid next to the vinegar in their kitchen, but in labs and factories, this chemical gets a surprising amount of use. It serves as a building block for medicines, dyes, and even some flavors. Yet, the same reactivity that makes it valuable can bring trouble if people get careless.

What Happens with Skin or Eyes

Anyone who’s spilled chemicals on their skin knows how scary things can get fast. Bromoacetic acid burns right through the outer layer of skin. Even a splash can leave a painful, blistered patch pretty quickly. Eyes sting even worse—a tiny droplet could mean lasting vision problems. I once worked with a tech who caught a drop on his wrist; he rinsed right away but still ended up with a wound that took days to heal.

Breathing and Ingestion Risks

Chemicals don’t just hurt from the outside. Fumes from bromoacetic acid can irritate the lungs, creating coughing fits or making it tough to catch your breath. Swallowing even a small amount brings on vomiting, muscle spasms, confusion, and internal burns. Hospitals have reported severe poisonings after accidental ingestion, sometimes requiring a ventilator and round-the-clock care.

Long-Term and Environmental Concerns

Some acids only hurt on contact, but bromoacetic acid has shown it might affect organs over time. Animal studies reveal liver and kidney damage can pop up from repeated exposure. Workers exposed for months can feel sick, tired, or notice yellowing of the skin—classic liver warning signs. In water, this acid lingers, killing aquatic life at low concentrations and disrupting the food chain. Local ponds turn lifeless where run-off leaks happen.

Can We Make It Safer?

Proper safety gear isn’t just a suggestion here. Thick gloves, goggles, and good ventilation keep the worst of the hazards at bay. In my lab days, nobody even cracked open a bottle without a full safety plan and a wash station close by. Spills required special neutralizing powder and never went down the drain. Replacing glass bottles with plastic-coated ones stopped accidents when a clumsy hand knocked something off a shelf.

Disposal also demands attention. Pouring unused acid into the trash or local water system means inviting major health and environmental damage. Most plants treat waste with alkalis until it tests neutral, then ship it off to chemical disposal pros. Some scientists now work on replacements that give the same lab results but break down harmlessly after use. That research shows promise, though substitutes need careful checks too.

Why We Should Not Look Away

Many chemicals disappear from the public eye unless there’s a big spill or accident, but dangers like bromoacetic acid stick around wherever industry or academic labs work with reactive compounds. Federal regulators rank bromoacetic acid as highly toxic. Every bottle comes with warning labels, yet injuries still happen. Clear education, updated safety protocols, and serious respect for its risks keep everyone safer. Protecting ourselves and our surroundings means treating every chemical, even those behind the scenes, like it matters—because it does.

Knowing What You’re Dealing With

Bromoacetic acid stands out as a nasty customer in any lab or industrial setting. It’s a strong alkylating agent, able to burn through human tissue and damage the eyes or lungs after brief exposure. Coming face to face with this compound years ago in grad school, I remember the sharp, sour smell and the way even a whiff made my nose sting. Gloves and a fume hood weren’t just routine—forgetting them meant risking serious injury.

Personal Protective Gear Is Non-Negotiable

Every time I see someone removing their gloves or skipping eye protection while handling corrosive chemicals, it sets alarms off for good reason. Nitrile gloves work better than latex because bromoacetic acid can chew through thinner materials. Lab coats, chemical splash goggles, and—always—a face shield if there’s a risk of splattering drive down the risk of personal injury. Shoes need closed toes. Synthetic fabrics help, not cotton, since natural fibers catch splashes and hold onto caustic agents dangerously. The best move? Always check protective gear for holes or tears before starting any task.

Working in a Controlled Environment

Bromoacetic acid should never leave a well-ventilated lab or a chemical containment hood. I met a researcher who trusted an open window and tried mixing reagents by her bench. Poor ventilation sent corrosive fumes straight into her face and hospital bills soon followed. Proper use of a certified fume hood keeps vapors and accidental splashes contained. Every safety checklist I’ve followed or written stresses: never pipette or decant this acid outside controlled ventilation.

Safe Storage Saves Lives

Forget to seal a bottle, and this chemical eats through plastic and contaminates shelves. Always keep containers tightly closed in chemical-resistant, labeled secondary containment. Keep it far from bases, reducers, and anything flammable. Labeling isn’t just a paperwork chore. OSHA records show that most serious lab injuries stem from poor labeling or improper storage, often mixing incompatible chemicals or confusing lookalike bottles.

Handling Spills Right

One time, a beaker with bromoacetic acid cracked as I picked it up. I shouted for help and hit the chemical spill kit. Commercial spill kits work well, but you need to know what’s in them and how to use them before trouble starts. Never reach for water—combine water with strong acids and reactions get violent. Neutralizing with sodium bicarbonate, then mopping up with plenty of absorbent material, stops the spread. After every spill, alert colleagues and let your safety officer know. Documenting what happened cuts down on repeat mistakes.

What Action Looks Like

Accidentally splash acid on yourself—immediate action makes the difference. Rip contaminated clothes off and flush skin for fifteen minutes with running water. If it hits your eyes, keep flushing and get medical help fast. Emergency showers and eyewash stations deserve a weekly check. I learned early that the location of these stations should come second nature. Over the years, drills and fast rehearsals have helped me react fast if incidents happen.

Building Good Habits

Routine safety training, updated material safety data sheets, and a team culture where speaking up isn’t frowned upon all lower the chance of accidents. Every protocol, every new face in the lab, needs to get the message that bromoacetic acid is unforgiving. If someone’s not sure about a step, giving them the time and space to double check beats rushing—and brings everyone home safe at the end of the day.